LOTUS EFFECT

New Development based on Nanotechnology

Nanotechnology

Manufacturing or use of nano-scaled systems* for the creation of special effects

*: 1 nm = 1/1 000 000 000 m

Examples of nature:

e. g. glitter beetle; nanostructures at the surface produce colours without dyestuffs and a self-cleaning effect

Examples for nanotechnology:

- Nano - engineering (nano engines)

- Nano - electronic (nano amplifier)

- Nano - surface modification (e. g. lotus effect)

Bacterial "engine"

Lotus effect:

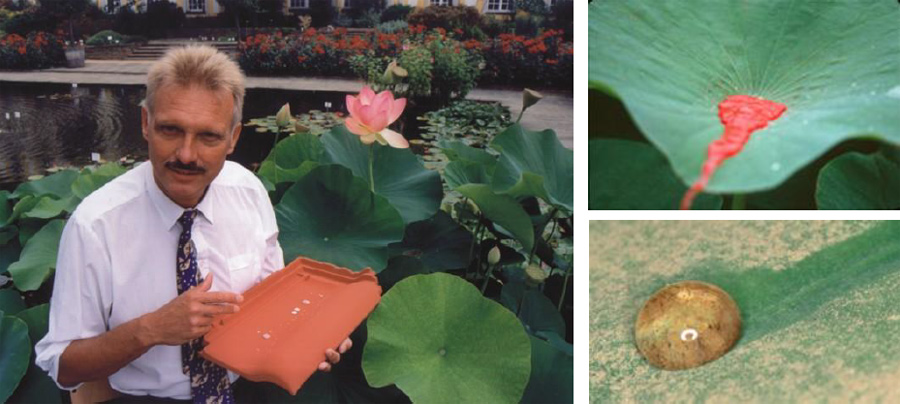

A self-cleaning effect which was first discovered by Prof. Barthlott at the lotus leaf. Dust and other pollutions are rinsed off by raindrops from a lotus leaf.

Professor Barthlott

In the meantime it is known on which physical principles the lotus effect is based. Many institutes and suppliers try to apply this effect on textiles, plastics, glass or other materials.

Facade paint, selfcleaning with rainfall thanks to the Lotus-effect®

Both private and public building owners know how dirty facades can become over time. On conventional paint coatings dirt particles accumulate and the surface itself becomes wetter and wetter. This leads to the formation of algae and fixation of particles on the surface, especially on the more shaded north and east facing sides of a building.

With StoLotusan Color protection, dirt runs off each time it rains to leave a beautifully clean and dry facade.

The first self-cleaning clay roof in the world:

- It stays clean for years in contrast to conventional roof tiles.

- The principle is revolutionary.

- The burned-in surface finish of this Erlus clay roof tile destroys dirt particles, grease deposits, soot, moss and algae with the aid of sunlight. The next rain simply washes the dirt away.

Functional principle

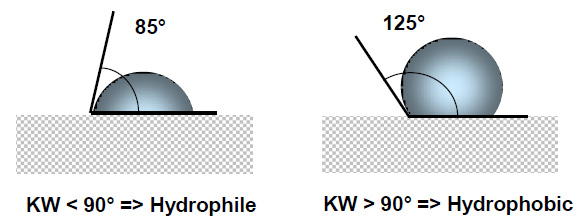

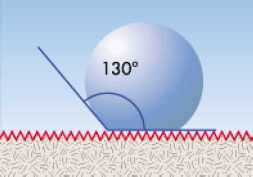

Precondition for a lotus effect:

1. Hydrophobic (water-repellent) surface

2. Nano-/microstructure on the fibre

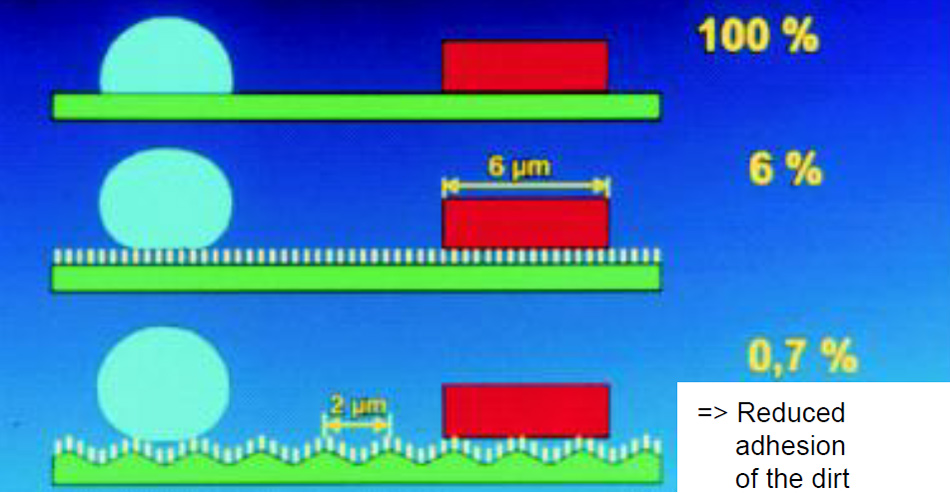

Effective contact surface of smooth and microstructured surfaces

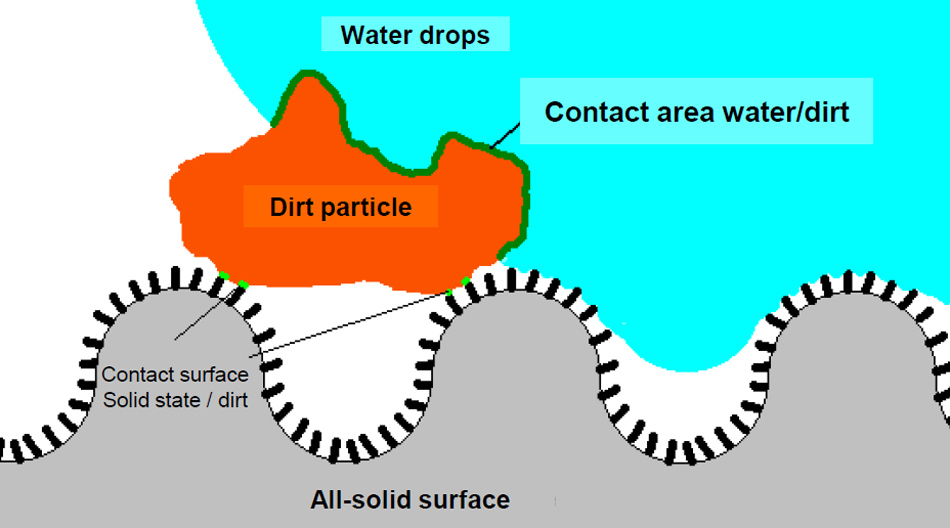

The structures on the fibre surface offer a lower adherence to the dirt particle (water drop).

Result:

=> Water drops pick-up the dirt

=> The surface is (self-)cleaned

Smooth Plain surface

Nano surface

Micro/nanostructures on a leaf (nasturtium)

THOR Development

2 Nano Poducts for the lotus effect treatment:

- CONTRAQUA LE 1

- CONTRAQUA LE 2

Main application fields: Awnings

Structure/consistency: Aqueous nano silica gel dispersion; free of fluorocarbon

Application: Standard technique (padding)

How does it work?

- Padding applications => water-based products

- Microstructures (1 - 20μm) => Textile, agglomerates

- Nanostructures (5 - 999 nm) => Nanoparticles, Aggregate

- Hydrophobic => Hydrophobic alkyl groups (no fluorine!)

Treatments and results

| (g/l) | Product | Awning 100% PES | Awning 100% PES |

|---|---|---|---|

| FC - resin | 85 | ||

| 1st. bath | CONTRAQUA LE 1 | 180 | |

| 2nd. bath | CONTRAQUA LE 2 | 260 | |

| Drying/curing °C | 150/120/150/3 min | 150/3 min | |

| Pearl effect | 4/5 | 3/3 | |

| Water column [mm] | 640 | 395 | |

| Self-cleaning effect | +++ | + | |

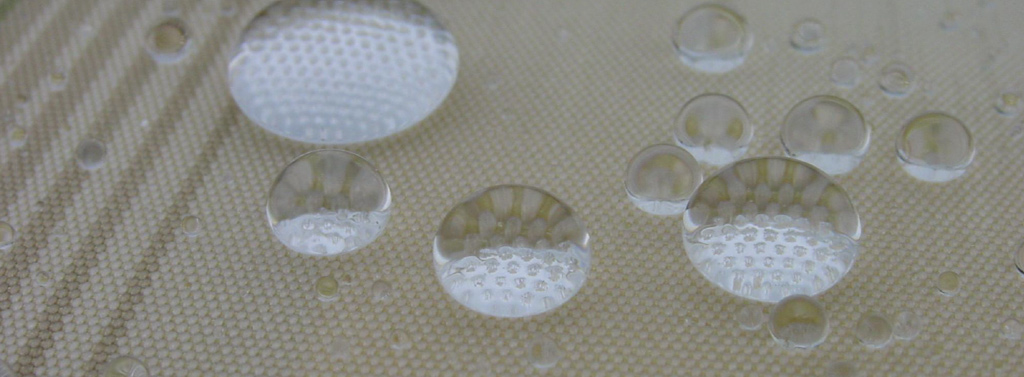

Water drop on a PES-fabric (awning) treated with CONTRAQUA LE 1/2

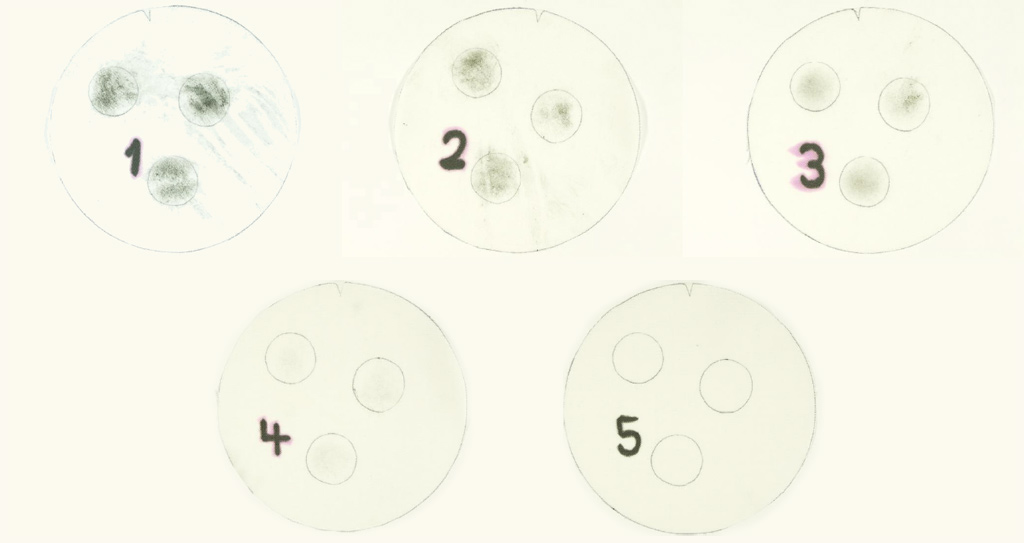

Test of the self-cleaning effect

Mark 1-3: no self-cleaning effect

Mark 4-5: self-cleaning effect

Honey drops which run down on a fabric treated with CONTRAQUA LE 1 / LE 2

Practical test (awning after 6 months)

Nanoimpregnation (Contraqua LE 1/ LE 2) / FC-impregnation

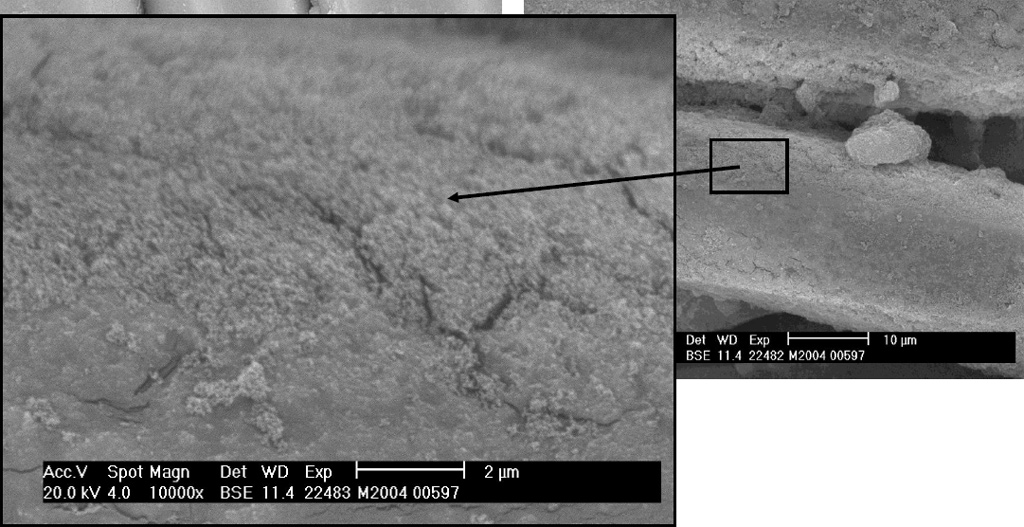

REM - pictures

PES - fibre with FC-impregnation / PES fibre with nanoimpregnation

Marketing

February 2006: After the successful long-term tests the company Schmitz/Emsdetten has introduced the nano-treated awning under an own name at the R & T Fair in Stuttgart.

Further development / expectations

- Self-cleaning foils (PVC, PU, PES)

- Improved permanency

- Other effects